Creating a table or bench out of concrete isn't as hard as what it may seem. In this article we will describe the entire process of creating a lightweight concrete table using a glass fiber reinforced concrete (G.F.R.C.). While the steps we list are used with a G.F.R.C. mixture, this entire process can be used with leftover concrete from a job. Whether your a hobbiest or a contractor, a good looking concrete table is a task that anyone can achieve.

Step 1: Gather Supplies

We obviously can't make a good looking table mold without the right supplies. A good glass fiber reinforced concrete (G.F.R.C.) mixture will be the main ingredient and the most important for a lightweight concrete table. We use Proline's ProCast. You will need one to two 5 gallon pails, depending on the thickness of table you want. For a full thickness live-edge table we used about 1 1/2 pails with the help of an insert (you'll see more about this later.)

The approach to coloring the table is up to you. However we found that to get a realistic wood look, a combination of integral color, accent color, and antiquing wash really made the table pop. Choosing a sealer is also based off of preference. We recommend a low gloss sealer when going for a realistic wood look. We use Proline's NatureShield because it can go on thin and will soak into the concrete with little gloss. Other miscellaneous items included a surface cleaner, like Dura-Clean, and a buffing pad to clean the concrete in between colorings.

|

Here's a full list of items we used to make this table:

2 Pails of ProCast

|

Step 2: Add ColorPacks to Water

|

|

If you are adding integral color to the concrete (which you should be),

we find that it's easiest to add the color straight to the water and mix it that way. This allows the color to evenly distribute throughout the concrete. |

Step 3: Mix in Slurry

|

|

When we are confident that the color has

mixed into the water completely,

|

Step 4: Rub Slurry into Mold

|

At this point you would think we would just

Note: Don't forget to add form release to the mold. |

Step 5:

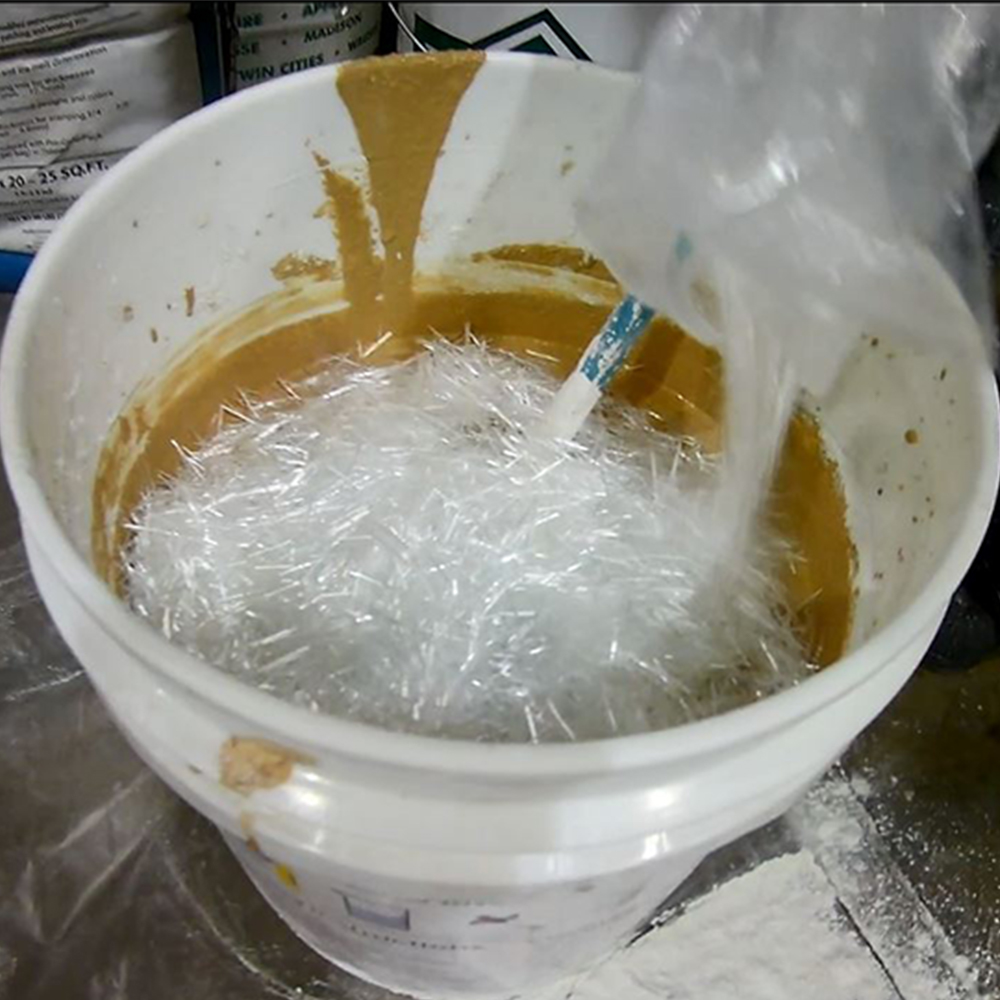

Add Fiber Glass and Mix

|

Now is when you can go ahead and mix in all of the fibers into the slurry. These fibers are what is going to give our concrete its strength without adding much weight and they are the G.F. in G.F.R.C. You'll also notice that the mixture will become thicker and more viscous after mixing them in. |

Step 6: Pour Mixture into Mold

|

Now is when you can pour the mixture into the mold. We used the rest of the bucket for this table before adding the foam insert. We used a portion of another bucket to fill in the edges (see below)

You have flexibility on how much concrete you would like to use. One bucket of ProCast can be enough, but the table will turn out to be thinner at 1-2 inches thick (like the one seen in Step 9) If you want to get a full thickness table, you will end up using around 1 1/2 or more, depending on the size of your insert. |

Step 7: Place Foam Insert

|

This is an optional step, but we highly recommend it if you're looking to make the lightest table possible.

We took two pieces of Styrofoam insulation, and cut it to fit the mold, with roughly two inches of spacing around the edges. We also wrapped the insert with plastic wrap so that it can be more easily removed later. |

Step 8: Fill In Edges

|

Not its time to fill in the gap you left between the foam insert and the mold. We recommend starting by weighing down the insert to prevent it from moving and so you can get a thinner top (lighter table) If you're doing a thicker edged table like we did, you're probably going to have to mix another pail for this step. We ended using another half pail. You don't have to be extremely careful, just fill in the gap the best you can. You can chip or wipe away any concrete that gets over the edge of the foam. Once you have the entire edge filled in, let it sit and harden. |

Step 9: Remove from mold and clean up edges

|

|

Once the table has dried, carefully remove it from the mold. This is where mold release will make your life easier.Take your time when you're pealing back the edges. |

Step 10: Clean

|

This is an important step because it is going to remove all of the residual mold release that were left on the surface of the concrete. |

Step 11: Accent Stain

|

|

Now's the time to get in touch with your artistic side because we are going to be staining the table. We used two different colors for this. |

Step 12: EZ-Tique

|

Step 12: Dry Buff

|

|

Step 13: Seal

|

|